Preventive maintenance is a critical aspect of ensuring the smooth operation of equipment and machinery in any industry. By implementing a preventive maintenance checklist, businesses can prevent equipment breakdowns and failures by ensuring that regular inspections and maintenance tasks are performed according to a predetermined schedule.

This proactive approach minimizes unexpected downtime, extends the equipment’s lifespan, and reduces overall maintenance costs.

What Is A Preventive Maintenance Checklist?

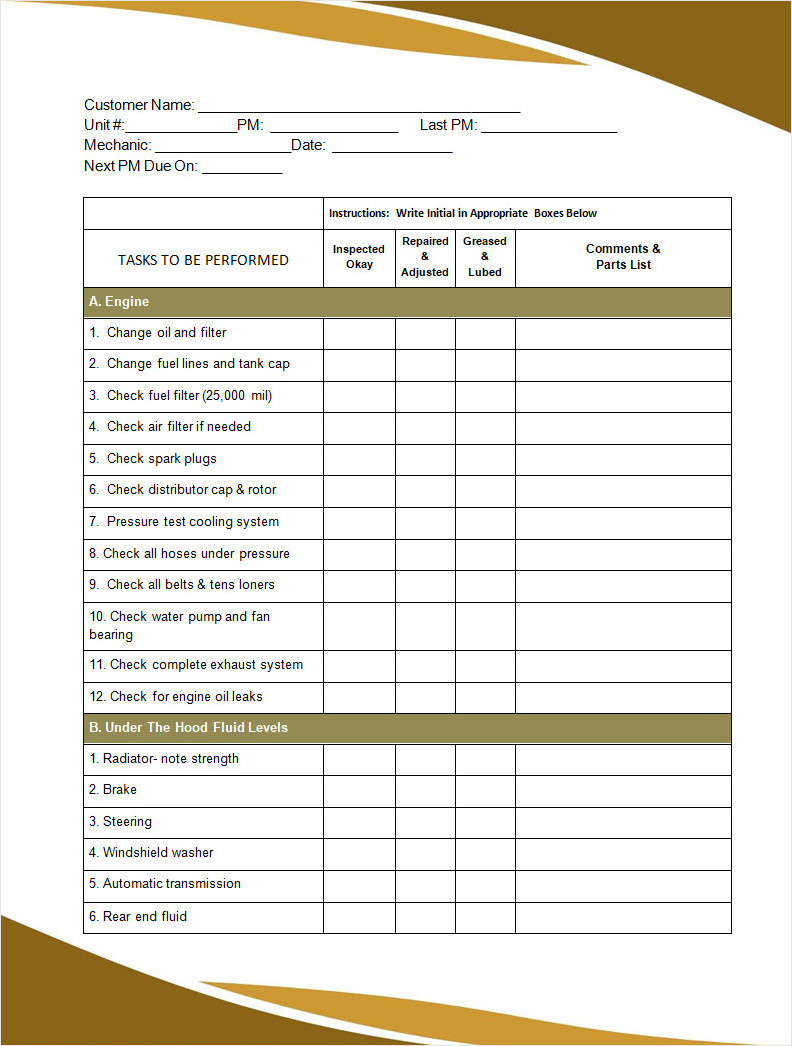

A preventive maintenance checklist is a detailed list of maintenance tasks that must be performed regularly to ensure the efficient operation of equipment and machinery. These tasks can include inspections, lubrication, cleaning, adjustments, and replacements of worn-out parts.

By following a preventive maintenance checklist, businesses can identify potential issues early on and address them before they escalate into costly breakdowns.

Benefits Of A Preventive Maintenance Checklist

There are several benefits to implementing a preventive maintenance checklist in your maintenance program:

1. Efficiency in Preventing Downtime

One of the primary benefits of a preventive maintenance checklist is its ability to minimize downtime. Unexpected equipment failures can lead to costly disruptions in production and operations. By staying ahead of maintenance tasks through a checklist, businesses can identify and address potential issues before they escalate, reducing the risk of unexpected downtime.

2. Prolonging Equipment Lifespan

Regular maintenance, as outlined in a preventive maintenance checklist, can significantly extend the lifespan of equipment. By addressing wear and tear, lubricating moving parts, and replacing worn-out components, equipment can operate efficiently for a longer period. This can result in cost savings by reducing the frequency of equipment replacements.

3. Cost-Effectiveness in Maintenance

Implementing a preventive maintenance checklist can lead to significant cost savings for businesses. By proactively addressing maintenance issues, businesses can prevent costly breakdowns that require emergency repairs or replacements. Regular maintenance also helps identify minor issues that can be fixed at a lower cost before they escalate into major problems.

4. Enhanced Operational Efficiency

Equipment that is well-maintained through a preventive maintenance checklist operates at optimal efficiency. Properly lubricated, cleaned, and inspected equipment is less likely to experience malfunctions or breakdowns, leading to smoother operations and increased productivity. This efficiency can translate into improved profitability for businesses.

5. Ensuring Workplace Safety

Regular maintenance as part of a preventive maintenance checklist plays a crucial role in ensuring workplace safety. Malfunctioning equipment can pose significant safety hazards to workers. By maintaining equipment in top condition, businesses can reduce the risk of accidents and injuries, creating a safer work environment for employees.

What Are The Different Types Of Preventive Maintenance?

There are three main types of preventive maintenance that businesses can implement:

1. Time-Based Maintenance

Time-based maintenance involves scheduling maintenance tasks at specific time intervals, regardless of the equipment’s usage or condition. This type of preventive maintenance is often used for routine tasks that need to be performed regularly, such as filter replacements, inspections, and lubrication. By following a predefined schedule, businesses can ensure that maintenance tasks are not overlooked and are performed consistently.

2. Usage-Based Maintenance

Usage-based maintenance involves scheduling maintenance tasks based on the equipment’s usage metrics, such as hours of operation, miles driven, or cycles completed. By tracking usage data, businesses can determine when maintenance tasks need to be performed to prevent wear and tear on equipment. This type of preventive maintenance is particularly useful for equipment that experiences varying levels of usage.

3. Condition-Based Maintenance

Condition-based maintenance relies on monitoring the condition of equipment through sensors, performance data, or visual inspections. Maintenance tasks are performed based on the equipment’s actual condition rather than a predetermined schedule. By identifying potential issues early on, businesses can address maintenance needs before they escalate into costly breakdowns. Condition-based maintenance is a proactive approach that helps businesses maximize equipment uptime and reliability.

Elements Of An Effective Preventive Maintenance Checklist

An effective preventive maintenance checklist should include the following elements:

1. Equipment Identification

Properly identifying equipment that requires maintenance is crucial for an effective preventive maintenance checklist. By clearly labeling equipment and machinery, maintenance personnel can easily locate and address maintenance needs. This identification also helps in tracking maintenance history and performance metrics for each piece of equipment.

2. Detailed Maintenance Tasks

A comprehensive preventive maintenance checklist should outline specific maintenance tasks that need to be performed on each piece of equipment. These tasks may include visual inspections, lubrication of moving parts, cleaning of components, calibration, and replacement of worn-out parts. By detailing each task, maintenance personnel can ensure that all necessary maintenance activities are completed.

3. Frequency of Maintenance Tasks

Specifying the frequency at which each maintenance task should be performed is essential for maintaining equipment reliability. Some tasks may need to be completed daily, weekly, monthly, or annually, depending on the equipment type and usage. By setting a clear schedule for maintenance tasks, businesses can prevent oversights and ensure that maintenance is conducted at appropriate intervals.

4. Assigning Responsibilities

Assigning responsibilities for each maintenance task ensures accountability and helps streamline the maintenance process. By designating specific individuals or teams to perform maintenance tasks, businesses can ensure that tasks are completed on time and with consistency. Clear roles and responsibilities also help in coordination and communication within the maintenance team.

5. Maintaining Detailed Documentation

Keeping detailed records of maintenance activities is crucial for tracking equipment performance and identifying trends over time. Documentation should include dates of maintenance tasks, tasks performed, any issues detected, and parts replaced. This information can help in analyzing equipment reliability, identifying areas for improvement, and planning future maintenance activities.

Tips For Using A Preventive Maintenance Checklist

Here are some tips for effectively implementing a preventive maintenance checklist in your maintenance program:

1. Regularly Review and Update the Checklist

Regularly reviewing and updating the preventive maintenance checklist is essential to ensure that it remains relevant and effective. As equipment evolves or operational needs change, maintenance requirements may also vary. By periodically reviewing and updating the checklist, businesses can adapt to these changes and ensure that maintenance tasks align with current needs.

2. Train Maintenance Personnel

Providing training to maintenance personnel on the proper use of the preventive maintenance checklist is crucial for its successful implementation. Training should cover how to perform maintenance tasks, use maintenance management software, and adhere to safety protocols. Well-trained personnel are more likely to follow the checklist accurately and efficiently carry out maintenance tasks.

3. Utilize Maintenance Management Software

Maintenance management software can streamline the preventive maintenance process by automating task scheduling, tracking maintenance activities, and generating maintenance reports. By utilizing software tools, businesses can efficiently manage their preventive maintenance program, monitor equipment performance, and ensure compliance with maintenance schedules. This technology can enhance productivity and effectiveness in maintenance operations.

4. Monitor Performance Metrics

Tracking key performance metrics related to equipment uptime, maintenance costs, and maintenance completion rates is essential for evaluating the success of the preventive maintenance program. By monitoring these metrics, businesses can identify trends, pinpoint areas for improvement, and make data-driven decisions to enhance maintenance efficiency. Performance monitoring provides valuable insights into the overall effectiveness of the maintenance program.

5. Implement a Preventive Maintenance Schedule

Developing a preventive maintenance schedule based on equipment requirements and operational needs is crucial for maintaining equipment reliability. The schedule should outline when specific maintenance tasks need to be performed, taking into account equipment usage, environmental factors, and production schedules. By adhering to a well-planned maintenance schedule, businesses can prevent unplanned downtime and extend equipment lifespan.

6. Establish a Preventive Maintenance Culture

Creating a culture of preventive maintenance within the organization is key to fostering a proactive approach to equipment maintenance. By emphasizing the importance of regular maintenance, promoting accountability, and encouraging participation in the maintenance program, businesses can instill a mindset of prevention rather than reaction. A preventive maintenance culture can lead to improved equipment reliability, reduced downtime, and cost savings.

Preventive Maintenance Checklist Template

Start using our free preventive maintenance checklist template today to schedule routine inspections, reduce equipment downtime, and extend the lifespan of your assets.

Preventive Maintenance Checklist Template – Word

- Free Student Reference Letter Template (Word) - February 22, 2026

- Free Printable Greeting Card Template - February 19, 2026

- Printable Homeschooling Schedule Template - February 18, 2026